A Vital Tool in Mineral & Petroleum Exploration

Mineral and petroleum exploration is a crucial aspect of the natural resources industry, as it aims to identify and assess the potential of a given area for the extraction of valuable minerals and hydrocarbons. The process of exploration involves the collection of geologic and petrophysical data that provides a comprehensive understanding of the geological conditions and characteristics of the target area.

One of the most critical aspects of mineral and petroleum exploration is the preparation of high-quality core samples, which are obtained through drilling with specialised coring drills. The core samples are then subjected to Core Analysis to obtain detailed petrophysical information about the rock and reservoir properties.

However, the core samples can also be prepared as thin sections, which provide geologists with an even more detailed understanding of the rock properties and their relationship with oil and gas reservoirs. Thin sections allow geologists to study the pore structures, grain size, and orientation of rocks, providing valuable information about the permeability and porosity of the reservoir rocks, as well as the potential for oil and gas accumulation.

The preparation of thin sections involves cutting a thin sample of the rock with a diamond saw and grinding it optically flat. The sample is then mounted onto a glass slide and ground smooth using progressively finer abrasive grit until the sample is only 30 μm thick. Thin sections are then placed between two polarising filters set at right angles to each other. The optical properties of the minerals in the thin section alter the colour and intensity of the light, which is observed by the viewer.

The interference patterns produced by the thin sections on the Michel-Lévy Interference Colour Chart are assigned a specific colour, based on the wavelength of light that is being amplified or cancelled out. For example, minerals with high refractive indices will produce bright, colourful patterns, while minerals with low refractive indices will produce dark patterns. By comparing the interference patterns, mineralogists can identify the mineral and determine its optical properties. This information is crucial for understanding the composition, texture, and formation of rocks and minerals and can be used to make informed decisions about mineral exploration and extraction.

Recommended equipment for Thin Section Preparation

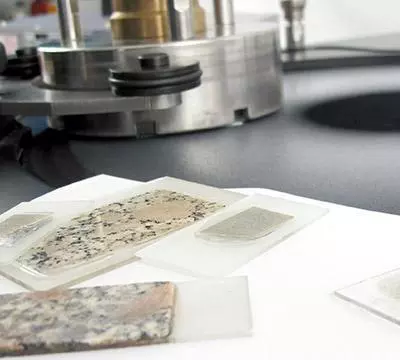

Thin section preparation is an important aspect of geological sample analysis. It involves the production of ultra-thin slices of rocks and minerals, which are mounted on glass slides for observation under a polarising microscope. This process requires specialised equipment and skills to produce the thin sections with precision and accuracy.

The KemTech III Thin Section Lapping Machine is capable of lapping and polishing thin sections mounted on glass slides to a thickness of 30 microns. The machine is equipped with an integrated peristaltic dispenser that applies metred doses of diamond and/or conventional abrasives to the lapping plate. The Lift Off Disc system allows for quick transitions between the lapping and polishing stages.

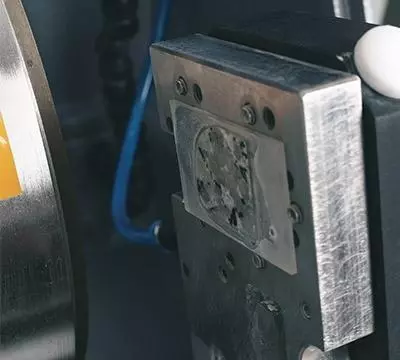

The Geoform is a highly specialised machine that can perform both cutting and grinding stages of thin section preparation in a single machine. The slide-mounted specimen is secured to a holder with a vacuum and then cut to a maximum thickness of 0.5mm with water cooling to prevent deformation and heat degradation. The grinding module has an adjustable grind position with an encoder displaying the grinding position on the HMI to 0.001mm resolution, ensuring the highest precision.

The Kemet range of geological sample preparation equipment is designed to cater to both high and low-volume production and can produce thin sections of the highest precision and accuracy. The use of specialised equipment such as the KemTech Geo and the KemTech III Thin Section Lapping Machine ensures that the thin sections are produced to the required thickness and quality for accurate analysis and decision making.